|

Automotive Metalization ApplicationsMustang Vacuum Systems is working with leading suppliers of vehicles globally on the next generation of metal reflectors and decorative applications, to ensure the highest quality parts and the most efficient cost of production.

The automotive industry as a whole is being driven to manufacture automobiles in a much more cost effective manner. Many parts have been made from metals, which are electroplated with chrome. Eco-friendly vacuum metallization produces no VOC’s and is an extremely clean process, which allows manufacturers to replace costly metal parts with less expensive, light weight solutions, which are coated with a thin film of a desired metal. The push toward vacuum metallization is allowing manufacturers to produce much more cost effective vehicle components. Mustang is a leading supplier of vacuum metallization systems for the automotive industry around the world. Our systems come standard with our patented high power cathodes which allow you to deposit a brighter, more reflective coating, faster than any of our competitors systems. Mustang’s high power, high throughput machines are based on our years of experience supplying global organizations that tell us pumping and power are cheaper than time. | Automotive App. | Process Description |

|---|

| Headlights,Taillights | Second surface reflective layer utilizing Mustangs patented in-chamber top coat. | | Exterior Trim, Interior Trim | Metalized decorative trim with UV cured top coat. Available in a variety of colors. | | Wheels | PVD metalized wheels using a combination of metal layers and powder coating. |

Forward LightingThis is the reflectance layer created typically on injection molded plastic for headlamps and tail lamps. We are capable of achieving 90% reflectivity with Al (aluminum) and 95% – 98% reflectivity with Ag (silver). Mustang’s reflectivity layer exceeds all forward lighting specifications. Mustang’s trademarked Plascoat greatly exceeds the required 10 minute NaOH test which is standard in the Automotive industry for headlamps. Our systems are designed to have extremely fast cycles for running in-line with injection molding machines. Below are the four steps to our extremely fast, high quality automotive lighting process.

車輪涂裝

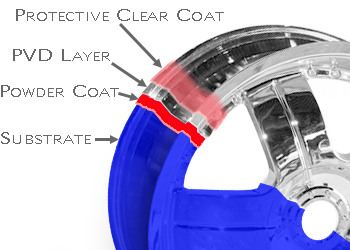

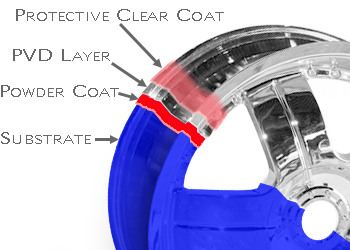

orking with industry leaders on effective alternatives to electroplated exterior trim, Mustang offers a wide range of metallization and surface preparation processes to enable ecologically friendly vacuum deposition solutions. Mustang’s broad experience enables us to address the complex adhesion issues faced by the industry for a range of substrates and paint combinations as specified by our customers. Mustang High Power Cathodes produce brighter more uniform coatings for complex high aspect ratio and complex three dimensional substrates, giving customers the look and feel of traditional electroplated metal parts. The photo to the left shows the layer stack of this process. In addition to standard PVD by sputtering, Mustang offers a number of deposition platforms to enable highly repeatable color solutions across a wide array of colors such as reactive sputtering, cathodic arc, PECVD and hybrid systems. Wheel Coating

Mustang is the leading supplier of systems for the latest process to replace electroplated wheels. This process combines powder coating, a thin metal layers and clear coat paint processes (pictured to the left). The benefits of this process are an improved ecological impact and reduced cost.

|