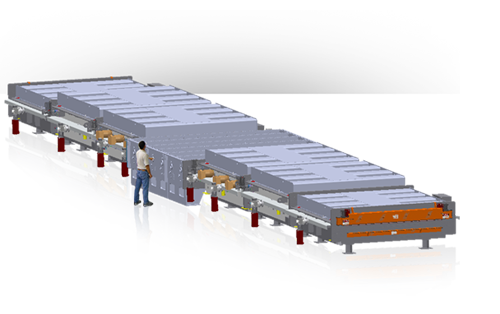

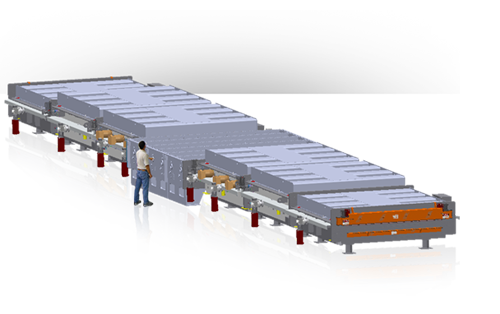

Horizon Series (In-Line Glass Systems)

12 The Horizon in-line system is a high throughput continuous coating system designed for single or multiple layer coatings on rigid substrates. Based on the designs of large area architectural glass coaters, the Horizon can be configured with or without substrate carriers, and with processing from above or below. Substrate loads, as single or multiple pieces, are staged from atmosphere or other controlled environments to a high vacuum environment, transitioned to a continuous controlled processing line speed through the process section, and transitioned back to atmosphere in a discontinuous staged process. Pre and post process surface treatments, heating and/or cooling can be incorporated into the staged entry and exit sections. The standard design is for float glass substrates between 1.5mm and 4mm thick, but other materials and thicknesses can be accommodated upon request. To achieve the highest uptimes the system is designed to minimize moving parts inside the vacuum chamber.The transport drive mechanism is external to vacuum, using a highly reliable vacuum feedthroughs for each required roller. Internal rollers use high temperature vacuum compatible dry bushings, and all lubricated bearings are outside vacuum. When applicable, features are available to minimize maintenance turnaround time and potential contamination from maintenance personnel. The Horizon can be placed in series or in parallel with other processing tools. We can provide external transport between tools or integrate signals with transport equipment provided by others. The systems are designed to provide an upgrade path from prototyping to start-up to high production, either as a staged supply or with pre-planned space for expansion. Standard Technical Specifications - Load size: 1350mm x 1350mm (2x 660mm x 1250mm)

- Load to Load Cycle Time: down to 20 sec. (Cycle Time dependent upon production requirements)

- Process line speed available to match load to load cycle time, servo-motor controlled.

- Drive belts external to vacuum for atmosphere maintenance.

- High vacuum pumping with 2000 l/s series turbomolecular pumps

- Substrate heating available to 300 o C (optional to 450 o C)

- Gap between substrates in process area: 20mm +/-10mm

- Two (2) gas selection per process section (up to four gases available)

- Uniform gas distribution along the length of cathodes. Adjustable length trim gas sections can be supplied based on layer uniformity requirement.

- Gas separation factor, if required, of >20:1 standard between layers using different gas mixtures.

- Process uniformity +/- 3% (available option to +/- 1.5%)

- Sputtering available with DC, Pulsed-DC, MF and RF

- Sputter orientation typically down without carriers. Can be sputter-up with carriers.

- On-line (in-situ) transmission and/or sheet resistance available on request

- System is designed for placement on a flat floor (no trenching required) with a raised platform to one side in the process area.

- Chamber covers are removed with an overhead or gantry crane

|